Brief introduction of perfume pump sprayer and its production process

- Share

- From

- HUFU.CLUB

- publisher

- GP Bottles

- Issue Time

- Oct 14,2021

Summary

It's hardly to say which part is the most important for perfume, but pump sprayer is the only path to touch the perfume.

Here we are going to talk about the sprayer | GP Bottles OEM ODM Manufacturing

Brief introduction of perfume pump sprayer and its production process

Spray categories

The main parts are made of polypropylene plastic PP, and the common specifications range from Φ11 to Φ28 screw neck. The amount of water output varies from 0.035ml to 0.4ml. The appearance has lace surface and smooth surface, as well as alumina shell decoration. Most of the plastic sprinklers are screw-type, a few are push-type seals, and the push-type is mainly used to try perfume.

Crimp type pump sprayer are the most common perfume nozzles. It is also the sprinkler with the most tacit understanding of today's theme. Common specifications are from 13mm; 15mm; 18mm; 20mm, especially 15mm. It is because 30ml, 50ml, 100ml glass bottles are usually equipped with the same size bottle mouth, so it is easier to match the nozzle.

What is the capacity of the water after spraying once. Common water output is 0.05ml; 0.08ml; 0.1ml; 0.12ml, etc., according to customer needs.

Plastic parts can be made in various colors, and the appearance of anodized aluminum is often made of gold, silver and other colors. Black, gun gray, etc. can be made, but individual colors are more difficult to make.

The middle sleeve is for fixing the bottle and the lid, and the style also needs to be well matched. The matching middle sleeve includes straight sleeve middle sleeve, step middle sleeve, bone position middle sleeve and so on.

Sprayer structure and composition

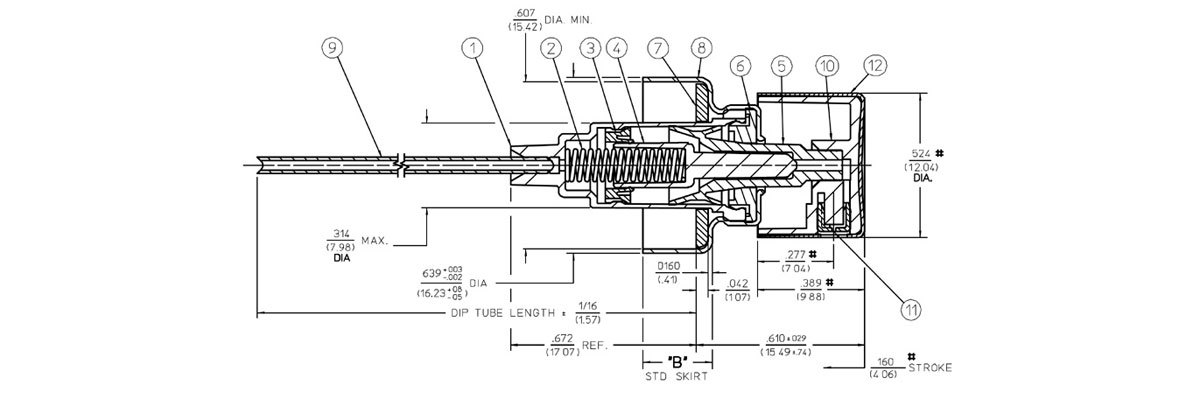

It is mainly composed of nozzle, pressing head, main rod, upper piston, gland, gasket, spring, lower piston, steel ball, pump body, and suction pipe. This is a two-spring pump structure, and there is also a single-spring pump structure.

working principle :

Simply put, it is the principle of atmospheric pressure. When the head is pressed down for the first time, the air in the pump body is compressed, the piston goes down, the steel ball (glass ball) is sealed with the pump body, and the air is discharged from the nozzle; in the process of pressing the head down, The elastic force of the spring causes the piston to rise, generating suction in the pump body in the sub-vacuum state, and the liquid is not blocked by the steel ball (glass ball) from entering the pump body; press again, the liquid in the pump body is subjected to the squeezing pressure, and passes through the main rod, presses the head, and the nozzle Spray; the cyclone groove of the nozzle makes the liquid produce an atomization effect.

Common problems during production

The perfume nozzle itself has many parts, and the perfect cooperation of the components can achieve good functions; at the same time, the good cooperation of the perfume nozzle with the middle sleeve, the perfume bottle cap, the container and even the outer packaging box is a product that can be introduced to the market and can be recognized by consumers The basics.

Developers of the following packaging materials can refer to:

Size: aluminum perfume nozzle, the size of the perfume sleeve should be confirmed according to the container (glass or plastic) and the matching perfume cap;

Due to the different heights and diameters of the bottle mouth (different customers, different styles), the optimal sealing effect can be achieved by adjusting the size of the aluminum shell of the nozzle; similarly, the matching middle sleeve also changes according to the pump head, and adjusts according to the size of the cap. , In order to achieve the proper tightness of the components matching;

Material: The conventional perfume middle sleeve should be made of alloy aluminum with a little higher hardness, and the aluminum on the nozzle can be made of medium hardness aluminum; in this way, the middle sleeve will not burst when pressed onto the pump head, and the appearance will not be affected; The material of the sheet (water-sealing sheet) can be selected from PE/SILICONE/RUBBER/NBR and other materials according to its own product characteristics, and it is necessary to test the response of the flavor to the gasket.

Compatibility: Some flavors or liquids may affect the functions of some parts of the pump head, so before using the pump head in large quantities, a compatibility test must be done; the objects are: the pump body/spring/gasket in contact with the liquid / Pistons etc. Case: The fragrance deforms the PP pump body, and the acid liquid makes the spring rust;